The AI-supported Finite Element Analysis: Accelerating Innovation in Vehicle Development

- VELA Group SE

- Jan 22, 2024

- 2 min read

Artificial Intelligence (AI) is playing an increasingly crucial role in product development, especially in the field of vehicle development.

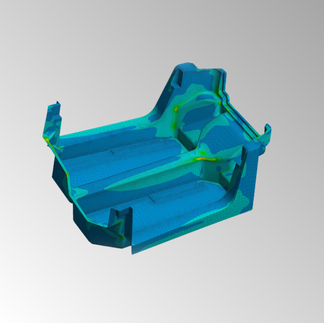

In particular, in simulation and calculation processes, such as Finite Element Analysis (FEA), AI already enhances performance in vehicle development.

AI procedures can aid in feature extraction from CAD models and force application, as well as in modeling and idealization decisions. AI techniques such as Algorithm Configuration, Regression of Parameters (SMAC), Clustering Approaches (ISAC), or Genetic Algorithms (GGA) are utilized. The use of these technologies assists engineers in complex tasks, thereby accelerating the development process.

A detailed description of AI methods can be found here:

What impact does AI support have on the development of products and vehicles in particular?

For us as component and system developers, the use of AI in FEM calculation presents numerous opportunities and advantages:

Design Optimization

AI can expedite the optimization process of vehicle components. Through the integration of machine learning, AI can identify better designs that combine strength and lightweight construction, leading to improved efficiency and performance of vehicles.

Automation of Simulation Processes

Automatic generation of FE models, defining boundary conditions and loads, and conducting simulations translate to time savings and efficient utilization of resources and project budgets.

Material Optimization

AI can assist in selecting and optimizing materials for vehicle components. By analyzing large amounts of data, it can identify patterns and trends to help engineers choose materials that enhance structural integrity while reducing weight.

Faster Analysis of Large Data Sets

AI can accelerate the processing of large data sets generated during simulations. Machine learning algorithms can recognize patterns in results, reducing analysis time.

Lifespan Predictions

AI can contribute to more accurate predictions of the lifespan of vehicle components. Continuous monitoring of sensor data and the application of machine learning can create predictive models to detect fatigue and potential failure points early on.

Topology Optimization

AI can support weight optimization of components. Machine learning can better understand complex relationships between form, structure, and performance, creating optimized structures that better withstand stress.

AI-supported simulation methods as a competitive advantage and innovation driver

For us as a development company, the ongoing integration of AI into development processes is a crucial factor in achieving the best solutions in even shorter periods. The goal is for AI to support our engineers in working more efficiently, precisely, and innovatively.

As an engineering service provider, this allows us to adapt more quickly to changing market conditions and customer requirements. Economically, AI will contribute to better products and vehicle solutions, becoming an increasingly significant innovation booster in the development of future-relevant vehicle concepts and technologies.

FIA-certified calculator

As one of the few companies in the world certified by the world motorsport authority FIA for safety structure calculations, we verify key component functions using these finite element analysis techniques:

• CAD pre-processing

• Modal analysis

• Harmonic response analysis

• Random vibration analysis

• Linear static analysis

• Topology optimization

• Nonlinear static analysis

• Analysis of composite materials

• Transient mechanics

• Explicit dynamics (crash analysis)

You can find more information about simulation here.