3D Scan Service

Scroll

3D digitization of

objects of all kinds

Create 3D scan data of components of various shapes, sizes and materials

With our 3D scanning service, we digitize objects and components of various types, shapes, and sizes.

For 3D digitization, we use a precise, high-resolution, portable 3D handheld scanning system that allows us to scan object surfaces ranging from 10 mm to 10 m in size. And all with an accuracy of 0.020 + 0.060 mm/m.

The result is three-dimensional digital point clouds, which are typically further processed and optimized. These point clouds can serve as a basis for surface reconstruction in CAD, as data for 3D printing, or as a foundation for further design developments.

The digitization process is completed with the editing and optimization of the scan data for improved further processing.

Facts about 3D scanning

FAQs about 3D scanning, 3D scan data, tolerances and much more. to click through:

1. What can 3D scans be used for, for example?

A 3D scan can serve as the basis for:

-

A new or optimized product design

-

Reproduction of rare or no longer available spare parts, e.g. for classic cars, tractors, or old production machines

-

Design and development of bodykits/aero kits

-

Manufacturing data for 3D printing or CNC machining of components

-

...and much more

2. Which objects/items can be 3D scanned?

Whether small, large, straight, or curved – we can scan virtually any type of object, such as:

-

Complete machines and machine components

-

Tools

-

Vehicles (cars, campers, vans, two-wheelers, commercial vehicles, buses, and more) and vehicle parts

-

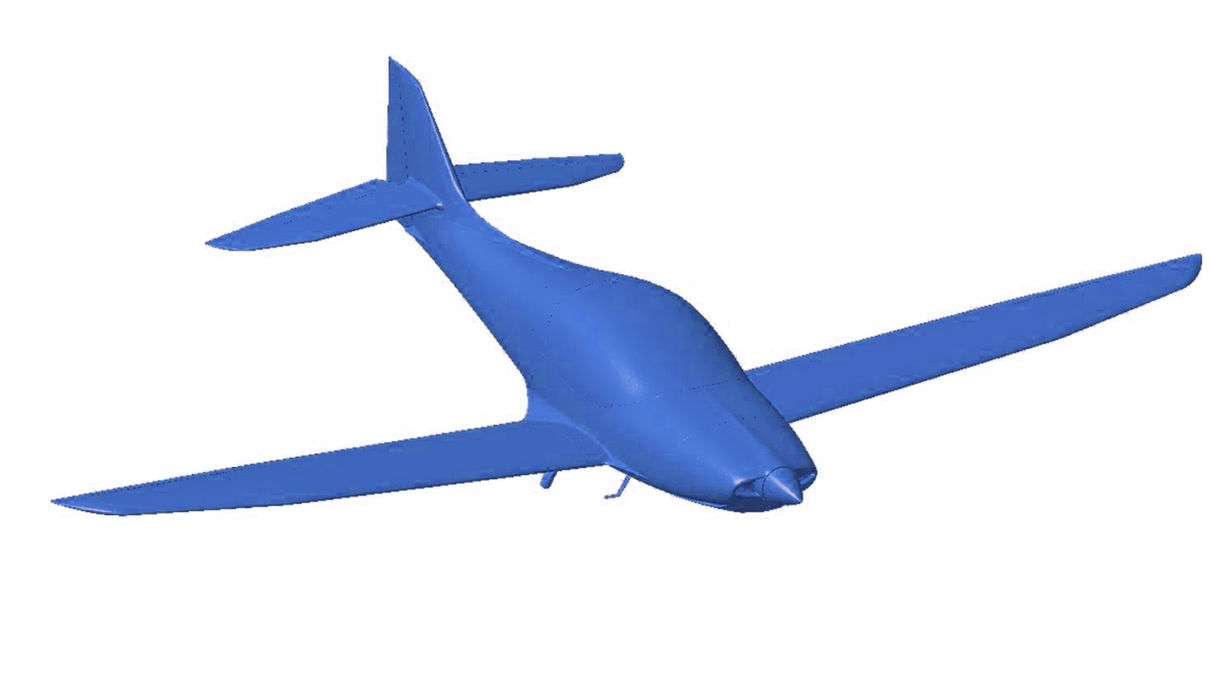

Airplanes, boats, and more

-

Medical devices and equipment

-

Orthopedic and rehabilitation technology

-

Art objects (e.g., sculptures)

-

Organic objects

-

Design models (milled, clay models)

3. Which sizes can be 3D scanned?

By using various scanner models, we are able to digitize nearly any size, shape, and material.

4. Do you also offer editing, optimization and further processing of 3D scan data?

Our service portfolio extends beyond 3D scanning to include the following services:

-

Optimization of 3D scan data

-

Data preparation for 3D printing or CNC machining

-

Surface reconstruction/reverse engineering and creation of a CAD model

-

3D modeling / CAS styling

-

Data comparison/quality assurance regarding manufacturing tolerances

-

Creation of first article inspection reports (FAIR)

5. How accurate are 3D scans?

Specifications of our high-resolution handheld scanning system from Creaform:

-

Measurement rate: 480,000 measurements/s

-

Scan area: 275 x 250 mm

-

Laser class: II (eye-safe)

-

Accuracy: up to 0.03 mm

-

Volumetric accuracy: 0.020 + 0.060 mm/m

-

Measurement resolution: 0.050 mm

-

Applicable part size: 0.01 – 10 m (larger objects available upon request)

6. Which 3D file formats are possible?

-

Polymesh file types: .obj, .stl, .fbx, .vrml, and more.

-

CAD / Parametric: .step, .sld, .dwg, .isam

-

Native formats: .ipt, .c4d

Other formats and file types available on request.

7. How much does a 3D data scan cost?

Thanks to our extensive experience and optimized processes, we can offer 3D scans of simple components starting at just €99!

To accurately assess the effort required, it is easiest if you send us multiple photos of the object from different perspectives in advance.

Alternatively, you can always send us your object. If you place an order, we will return it to you free of charge.

In general, the price for a 3D scan depends on several factors:

-

Size of the object

-

Color and surface texture

-

Amount of undercuts/shading (photo)

-

Location/environment for on-site scanning

8. Is an on-site scan possible?

We have several mobile scanners and also carry out on-site scans.

Ask us about the options and costs.

9. How long does a 3D scan take?

The time required primarily depends on the object to be scanned. Small, geometrically simple objects can be scanned within half an hour.

Large, complex components, vehicles, airplanes – depending on the requirements (without data processing) – can take several hours up to two days.

The scanning process

Using the example of a complete vehicle – from the physical object to the 3D scan data set:

1. Attach targets

Reference markers (targets) must be applied to the objects being measured in order to reference the measurement system.

These can later be easily and completely removed without leaving any residue.

2. Digitize

The component/vehicle is now being digitized.

Shiny or highly reflective objects must be treated with a spray.

The spray mattes the reflective surface of the object and leaves a thin, white mist. It is sublimating and can also be easily washed off.

3. Edit scan

The individual partial scans of the vehicle/scan object are secured, processed, and prepared for assembly into a complete scan.

4. Align scan

The individual sections of the scan object are positioned and assembled into a complete model.

Using a generated symmetry plane, the complete model is aligned to the origin and optimized for further processing in the CAD system.

5. Final 3D Scan

The scan model is now being exported as an STL file.

IMPORTANT: These scan data do not represent constructed surfaces, including wall thickness, but are purely point clouds/polygon meshes.

These data serve as the basis for the following applications:

-

Dataset for 3D printing

-

Base data for CAD construction

-

Base model for reverse engineering

-

Dataset for mechanical processing, milling, etc.

-

Test model for static and dynamic structural analysis (FEM)

-

Test model for quality assurance (QA)

the 3D data set

The result: polygon meshes/point clouds – no parametric CAD models

Original component

Functional component

Ignition starter ring produced on behalf of the customer for reproduction.

3D Scan

Polygon mesh as STL

Digitized component with an accuracy of up to +/- 0.03 mm deviation from the original.

CAD data set

Parametric CAD model

To display the characteristics of the polygon mesh model, we place the redesigned CAD model (not included in the scope of the scan) over the scan data.

Comparison

3D Scan vs. CAD model

-

Scan rounds off component edges.

-

Drillings are not through holes.

-

The scan is a polygon mesh shell, not a CAD model.

-

Recommendation/Solution: Reverse Engineering (surface reconstruction or component reconstruction).

APPLICATION POSSIBILITIES

3D scan data in STL format can serve as a basis for:

3D printing

Processed 3D scan data can easily be processed by 3D printers. It is important to export the data in compatible file formats.

To ensure good print quality, the 3D scan should be optimized beforehand.

Reverse engineering

The digitized component serves as the basis or template for our re-engineering process.

Through CAD-supported surface reverse engineering of the digitized mesh lines (3D scan in STL format), our engineers reconstruct manufacturing-ready CAD data sets.

You will receive a high-quality 3D scan. The file, in STL format*, contains the digitized object as a polygon mesh (faceted model).

* other file formats available upon request.

Depending on the application, component complexity, and precision requirements, the STL object can be manufactured using 3D printing or mechanical manufacturing processes.

However, the internal structure of the components, such as closed cavities, cannot be captured by optical measurement systems.

In most cases, surface reconstruction is still required to create 3D data models.